Globally supply chains have been disrupted, manufacturing processes halted, and demand for non-essentials has slumped. As the pandemic evolves, most businesses find themselves reassessing their supply chain strengths and gaps. According to the National Association of Manufacturers (NAM) survey, manufacturing operations have been affected by more than 50% due to supply chain constraints.

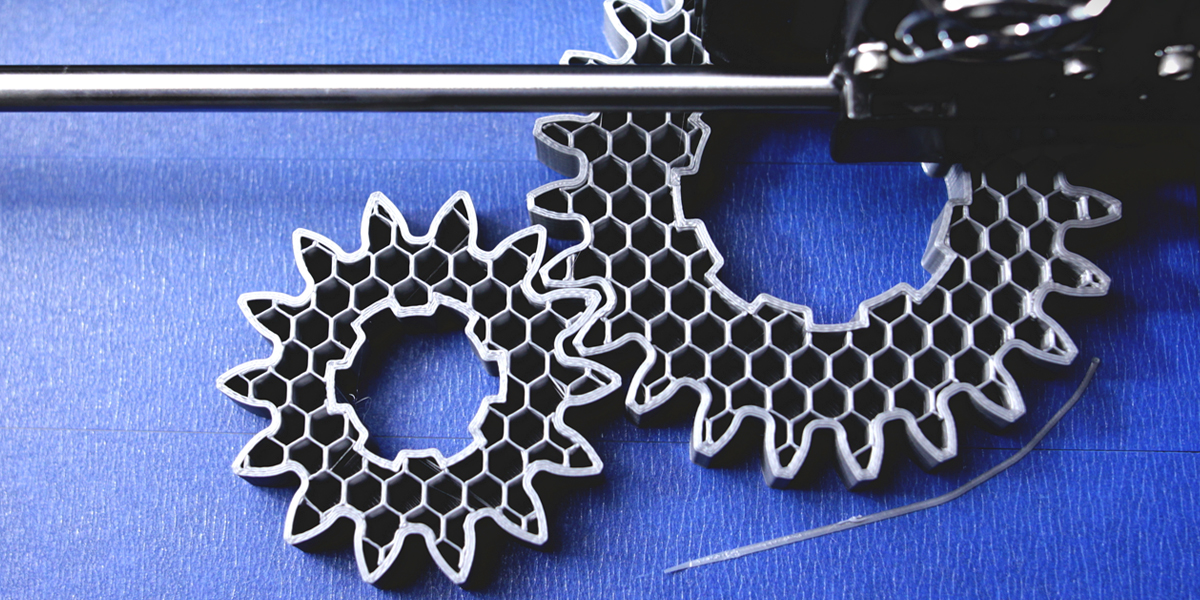

For companies to address immediate business needs without depending on supply chains, 3D printing (3DP) is emerging as a slow but sure solution. 3DP has been considered by a bevy of industries from construction to consumer electronics and beyond. Advanced utilization of this technology has been witnessed in aerospace, medical customizations, automotive, and manufacturing. Prior to the COVID-19 crisis, these sectors employed 3DP majorly for rapid tooling and prototyping. However, in the post COVID-19 world 3DP is expected to drive deeper implementations through direct manufacturing.

Unclogging supply chain bottlenecks

Extreme demand and supply volatility is one of the key reasons for companies to turn to 3DP solutions. Hence, its domestic adoption across geographies is estimated to rise, mainly to limit import costs and dependencies. Moreover, 3DP may be the only answer to mitigate resiliency challenges posed by current supply chain systems. The inconveniences of replacing suppliers during such a time adds more reason for companies to consider 3DP.

The future could also see businesses depending on 3DP for on-demand manufacturing requests. In the medical space, 3DP is already being used to create dentistry implants and PPE like test swabs, goggles, masks, and others. A good case in point would be Ford Motor company, which plans to assemble more than 100,000 face shields per week using 3DP.

Enhancing manufacturing capabilities

By adopting 3DP, companies will no longer have to forecast demand and stock up on spares from multiple suppliers. Instead they can create their own IP-protected digital models and manufacture them in-house, eliminating multiple risks that plague traditional procurement models.

The post COVID-19 world is expected to see pertinent examples of this in play, especially across the automotive and aerospace sectors. In automotive, the current disruption has compelled automakers to use 3DP to produce complex and performance-critical parts, for now. If found efficient over the long term, the solution could even be integrated into assembly lines.

Regional factors driving 3DP adoption

North America

Some OEMs are already facing reliability issues with spares, and have started looking at alternative suppliers in other regions to mitigate supply chain risks associated with the pandemic. Moreover, given the US-China triggered trade war that has spiked import tariffs in the US, several companies have chosen 3DP as a sustainable option to replace their imports.

Europe

Claiming the second-largest share of the global 3DP market, EU nations like Germany, Italy, the UK, and France are leading the adoption race. These regions along with a few others house over 700 3DP focused firms, earning Europe the credit for being a highly conducive market for 3DP proliferation, acceptance, and adoption. The onset of the pandemic saw the European Commission appeal to 3DP companies across these regions to support various hospital needs like the creation of masks and ventilator parts.

Actionable steps for companies to overcome COVID-19 related supply chain challenges:

Short-term:

- Mitigate supply shocks by communicating with existing suppliers to avoid bottlenecks once things get back to normal (or the new normal). Focus on prioritizing 3DP-ready and regional capabilities.

- Work out a cost versus risk versus business continuity plan while including innovative suppliers that employ resilient supply chain technology solutions.

Medium-term:

- Ensure operational preparedness by evaluating inventory management tools to reduce human dependencies.

- Diversify procurement from different regions while assessing each supplier’s competitive advantage to stay better equipped for the future.

Long-term:

- Identify current supply chain gaps and evaluate the potential of 3DP and similar technologies to build supply chain resiliency.

- Assess how 3DP, in times like the COVID-19, can be integrated into existing manufacturing processes and benchmark its long-term business value against traditional manufacturing.

How Netscribes can help

The COVID-19 outbreak has left businesses across sectors in the lurch, grappling for a survive-and-thrive roadmap ahead. Amidst such trying times, what companies need is accurate, reliable, and timely insight into the latest market and consumer developments. For over two decades, organizations across the board have partnered with us for such data-driven and domain-specific market research and intelligence. Our global presence combined with diverse research experience helps us gear our clients with actionable insights to power their technology investment decisions. To know how we can help you, please contact info@netscribes.com